Why choose S3i stainless steel wire cable balustrade

Balustrade Wire FAQ

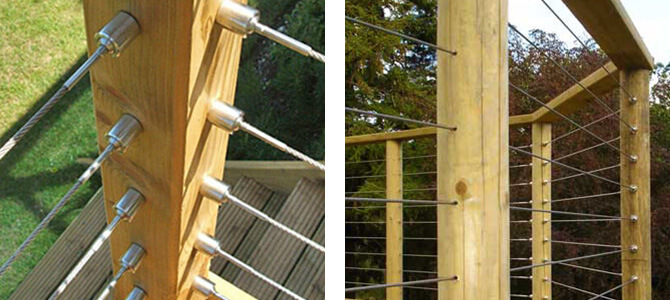

Our most popular and versatile wire balustrade system. Produced from high quality 316 (marine) grade stainless steel, with a choice of flat surface mount and tubular mount styles available.

Flat Mounting Balustrade Wire SystemFlat mount wire balustrade railing is engineered to fit to flat timber, masonry surfaces and flat profile stainless steel balustrade posts. You can choose from either our bespoke 'Flat Surface Mount - Made to Measure' balustrade wire system or the ever popular DIY - Flat Mount balustrade wire kits. |

|

Tubular Mounting Balustrade Wire SystemTube mount wire balustrade railing is designed to fit 42.4mm diameter balustrade posts, perfect for use with the Modular Balustrade System. Choose from either our bespoke 'Tubular Mount - Made to Measure' balustrade wire system or our DIY - Tubular Mount balustrade wire kits. |

|

Stainless Steel Wire Balustrade Systems and Kits

Video: Installation guide for flat mount made to measure balustrade wire.

How to install the made to measure flat mount balustrade wire system.

Please click for DIY flat balustrade wire kit installation advice.

What types of post should I use?

Any soft or hardwood timber baluster post would be suitable. You can mount cables to tubular metal balustrade posts and also flat steel surfaces.

|

You can also mount the cables to masonry brick walls which, dependent on your application, may eliminate the need for a post. |

The diameter of the fixing socket is 25mm (1") so any post of more than 50mm or 2" will suffice.

How frequently should I install an upright post?

You should try and space upright posts every 1.5 to 2 metres.

How far can I run a cable?

Our wire balustrade system can run for around 12.5 metres and still achieve good tension. You can run the cable through intermediate posts with a clearance hole of just over 7mm diameter.

Will the cables run up staircases or steps?

Yes. Our popular cable railing system has a ball & socket joint which will articulate up to 42 degrees as you can see below. This is also the maximum allowable rake angle permitted in current building regulations.

The stainless steel wire rope also has a natural degree of flexibility to follow angles. In the example below the stainless steel wire rope is passing through the post and naturally following the angle of the steps.

Can run the cable railing round corners?

No. It is very difficult to apply equal tension when passing the cable railing through corner posts. You must terminate the wire rope balustrade at each side of a corner post.

Shallow angles are possible as you can see above right. The inclusion of a handrail will help to strengthen the balustrade as a whole and improve the opportunities to run cables through posts at shallow angles.

How many horizontal runs of balustrade wire should I have?

The ultimate answer is yours and is a common sense balance between safety considerations, aesthetics and cost. You should however make yourself familiar with local building or planning regulations if you have any doubts.

The sensible recommendation is to space your cables at 100mm centres - that is, every cable set 100mm apart.

Quality and Care

Where are these cables made?

All the fittings are designed and manufactured here in the UK.

- This gives you peace of mind that we can offer:

- Full material compliance and traceability

- Assurance that these products offer full design conformance

- Batch testing during manufacture

- Full in-house and independent testing facilities

- Conformance certification available for all these products (please request when ordering)

- Efficient returns and replacement

How strong are the deck railing wires?

The assemblies have been sample tested to a break load in excess of 500Kg. Which is approximately the weight of 6 or 7 people. When tested to this level the assemblies didn't break or show any signs of stress or fatigue.

Do they rust?

The lifespan of this product is obviously subject to many different atmospheres. For example, an installation by the coast will have a different lifespan to an inland rural location.

Marine grade stainless steel will not rust unless it is subject to a particularly harsh environment or abused.

You should expect many years of trouble free enjoyment.

How should I clean the wire assemblies?

Spray with WD40 or similar and rub down with a cloth.

Balustrade Wire Regulations

Basic Rules

Please understand that the following basic rules are a guide only. Please refer to the official Building Regulations Section K2 documents (downloadable below) for detailed information.

Guards (balustrade) must be fitted to an edge where there is a drop of more than 600mm.

The height of the handrail must be a minimum of 900mm for all areas in internal residential applications.

The height of the handrail must be a minimum of 900mm for stairs and ramps in external residential and commercial applications, and a minimum of 1100mm for all other areas (balcony, floor edge).

Balustrade infill - such as wires, bars or spindles - should not be able to trap a child. You should NOT be able to pass a 100mm sphere between the gaps of the infill.

Official publications referring to regulations

Building Regulations Part K 2000 download here

The Building Regulations 2000 - Protection from falling, collision and impact

Timber Decking Association Statutory Requirements download here

Timber Decking Association Technical Bulletin regarding the planning and building control requirements of Local Authorities applicable to timber deck structures.

Timber Decking Association: www.tda.org.uk

Disclaimer

You should always check with your Local Planning Office to confirm that horizontal wires will be acceptable in your specific application.

Please note that it is YOUR responsibility to ensure you have understood and complied with any local or national planning guidelines or regulations. S3i Ltd (or any of its employees) will not be held responsible for outcomes related to the failure to satisfy any such guidelines or regulations.