Safety Shackles - Stainless Steel - E Type Safety Pin

E Type Safety Shackles in A4-AISI 316 Grade Stainless Steel

Safety Shackles

Designed for lifting applications where a high level of corrosion resistance is required.

Every shackle is proof tested to 2 x WLL and inspection certificates BS EN 10204 3.1b are available on request.

|

|

|

|

||||

E type Safety Pin Shackles are manufactured from stainless steel EN10088 1.4401/4 sourced from European mills. They are produced using the latest technology in upset forging and are consequently of a very high standard.

This range of shackles has full material traceability, CE marking and test batch identification. They are supplied with test certificate type EN10204 3.1b.

Our product tables show standard sizes. Other sizes are available on request and can be manufactured to order.

|

Need to knowEvery safety shackle is proof load tested to 2 x WLL,CE marked and certificated to BS EN 10204 3.1b.The lead time for testing is 7-10 days. |

Information

The shackles with E type Safety Pin are manufactured from Stainless Steel EN10088 1.4401/4.

The shackles are manufactured to a very high standard using the latest technology in upset forging.

The special bolt end ensures the nut is positioned correctly allowing sufficient room for the split pin.

This range of shackles benefits from full materials traceability, CE marking and test batch identification. Supplied with test certificate type EN10204 3.1b.

Technical

E Pin shackles (D and Bow) are manufactured from ISO 1.4401/4 stainless steel and are proof-tested to twice their Working Load Limit (WLL) using equipment calibrated to BS EN 10002-2 and NAMAS NIS 0424.

Design & Application

Stainless steel E Type shackles should be used in applications where corrosion resistance is of significant importance.

Stainless steels are possible solutions to corrosion problems and are ideally suited to natural (water, city and landscape atmospheric) conditions.

Stainless steel E Type shackles should NOT be used in general lifting applications where corrosion resistance is not required. For such general lifting applications please refer to the PH range of lifting shackles.

Due to the nature of stainless steel and the possibility of work hardening/stress ageing, we strongly recommend that thorough inspection and maintenance is carried out on a regular basis.

Product information

E Type shackles (D and Bow) are made from EN10088-3 1995 1.4404 stainless steel, a work hardening Austenitic stainless steel.

Because of the critical dependence of the strength characteristics on the mechanical history of the material the shackles should not be used if distorted in any way, it is imperative that no attempt is made to straighten or modify the shape of these shackles for whatever reason.

ALWAYS:Storing and Handling Shackles

Never return damaged shackles to storage. They should be dry, clean and protected from corrosion. Do not alter, modify or repair shackles and never replace missing pins, bolts etc., but refer such matters to a competent person.

Never galvanise or subject to other plating processes without the approval of the manufacturer Working Load Limit (WLL)

The Working Load Limit refers to static loading - care must be taken to ensure that any shock or dynamic loads do not exceed the WLL.

Spreading of load

The load must not be concentrated over a small area e.g. by knife edges or small diameter steel ropes.

Operating temperature

If the intended environment of the shackle involves elevated or depressed temperatures please refer to the temperature tolerance chart below or call us for advice.

Temperature |

New working Load |

|---|---|

| 0 - 200° c | 100% of original working load |

| 200 - 300° c | 90% of original working load |

| 300 - 400° c | 75% of original working load |

| Over 400° c | Not allowed |

Technical information - Analysis

Please refer to EN 10088-3 1995 for chemical analysis and typical mechanical properties of 1.4401 and 1.4404 steel, which are also commonly known as grade 316 and 316L

Assembly

The bolt and shackle body will screw together easily and should be firmly fastened. Do not use any threading pastes or other such products which may attract or hold small pieces of dirt or metal.

Proper Use

Instructions for proper use

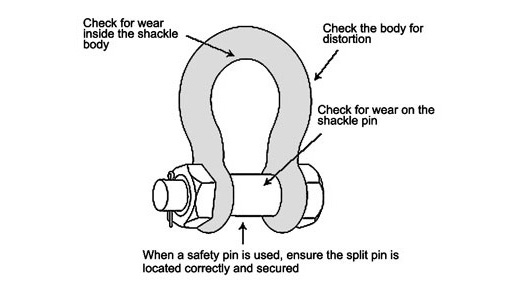

Shackles should be inspected before use to ensure that:

Inspection of shackle

Before the shackle is first put into use it should be examined for signs of damage.

If it is known, or suspected, that the shackle has been subjected to an excess load or the shackle shows any sign of cracking, splitting or deformation it must be destroyed.

It is required that the shackles are regularly inspected and that the inspection should take place in accordance with the safety standards given in the country of use. This is required because the products in use may be affected by wear, misuse, overloading etc. with a consequence of deformation and alteration of the material structure. Inspection should take place at least every 6 months and even more frequently when the shackles are used in severe operating conditions.

Super Duplex Stainless Steel

In instances where superior corrosion resistance is required shackles can be manufactured to order in super duplex stainless steel.

Safety critical applications such as the offshore industries may require marine fittings and shackles in super duplex stainless steel.

Please contact us with any enquiries for super duplex products.