Wireteknik Swaging Machine - A100

A100 Wireteknik Swaging Machine complete with Hydraulic Hand Pump

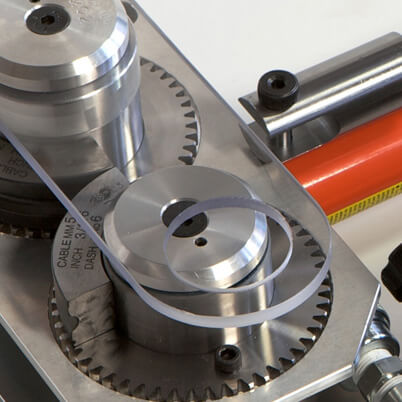

A100 Wireteknik portable roll swaging machine for swaging rigging hardware to stainless steel wire rope, with low weight and small outer dimensions making it extremely portable.

Wireteknik Swaging Machine A100

| Options | Swaging Range (mm) |

Weight (kg) |

Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|

| A100 | 1.6 - 5 | 11 | WT-A100 | £4,615.50 | |

| Die 1.6mm | 1.6 | N/A | WT-A100-016 | £205.50 | |

| Die 2.5mm | 2.5 | N/A | WT-A100-025 | £205.50 | |

| Die 3mm | 3 | N/A | WT-A100-030 | £205.50 | |

| Die 4mm | 4 | N/A | WT-A100-040 | £205.50 | |

| Die 5mm | 5 | N/A | WT-A100-050 | £205.50 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

Please Note: Delivery charge of £24.00 inc VAT applies to Wireteknik Swaging Machine.

The A100 includes a hand pump. All machines include full sets of pullers.

Note: Dies sold separately, Please contact us for full brochure.

Fully approved by Lloyds Register of Shipping.

Swaging range: 1.6mm (1/16 in) to 5mm (3/16 in).

Dimensions: L 440mm (17 1/2 in) x W 300mm (11 3/4 in) x H 135mm (5 1/4 in).

Weight: 11 kg (24 lbs).

Typical Applications

Architectural, like balustrades and railing.

Scenographic use at theaters for hanging and supporting set pieces.

Onboard joining of towing lines for NATO´s aviation practice targets.

Shop fitters use it to make spectacular product displays for their customers.

Standing rigging for sailing dinghies and lifelines on yachts.

Structural rigging for hang gliders and ultra-light airplanes.

Optional Hydraulic Power UnitsPUH-1 Hydraulic Pump Swaging speeds vary depending on type of cordless drilling machine. Typically a mid size machine with 1500 Rpm will give about 10 mm/second of swage-speed on a Wireteknik A200 Swager.  Please contact our Sales and Technical Team for pricing and further information on 01302 752 504 or email us info@s3i.co.uk. |

Operating Instructions

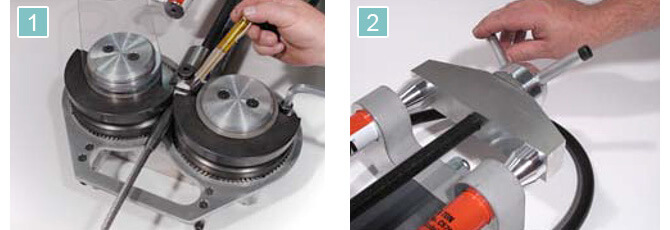

1. Choose the pair of roller dies that corresponds to the cable diameter, and slip them onto the cogwheel synchronizing pins. The arrows on the dies should always be in the swaging direction. |

2. Attach the terminal to the attachment fixture on the drawbar, and adjust the length so the roller dies meet the terminal shank at desired position. |

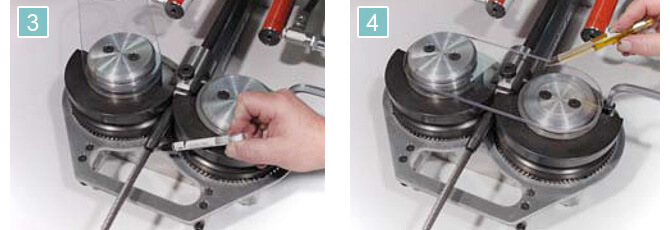

3. Apply just enough hydraulic pressure so that the roller dies holds the terminal firmly. Then mark and insert the cable into the bottom of the terminal throat. |

4. Move the transparent protective shield into position. Apply hydraulic pressure to draw the terminal between the roller dies. |

5. When the roller dies rotate, they will press the terminal shank onto the wire rope. |

6. Measure the diameter of the terminal after swaging, and compare with the swage dimensions list. |

Note:

The swager is designed to reduce the terminal shank to required diameter in one pass. However dimension variations of terminals, cables or material hardness could make it necessary to pass the terminal twice.

Product Information Downloads Here:

|

PDF Operating Sheet |

PDF Information Sheet |