Black Balustrade Wire Kits | Tube Mount

Tubular Post Mount Blackened Stainless Steel DIY Wire Balustrade Kits

Self Assembly Individual Black Balustrade Wire Kits, Tube Mount

New tube mount balustrade wire kits - designed with a stylish and modern look in mind, all components are produced from 316 marine grade stainless steel and are chemically blackened to achieve a finish that is on-trend and visually appealing.

Each kit is supplied with with everything you need to install a stylish balustrade infill onto 42.4mm diameter posts.

Priced as individual wire assemblies.

Each kit will make one single wire only; and are not designed to make multiple lengths out of one kit.

Designed and manufactured here in the UK.

Bare Cable End and |

Tension Fitting |

Black Balustrade Wire Kit - Tube Mount

| Options | Wire Ø (mm) |

Wire Length (metre) |

Tube Mount Sockets | M6 Screws | Tension Fitting | DIY End Fitting | Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|---|---|

| 1 Metre Kit | 4 | 1 | 2 | 2 | 1 | 1 | B4-TB-04-1-A-BLK | £47.94 | |

| 2 Metre Kit | 4 | 2 | 2 | 2 | 1 | 1 | B4-TB-04-2-A-BLK | £50.40 | |

| 3 Metre Kit | 4 | 3 | 2 | 2 | 1 | 1 | B4-TB-04-3-A-BLK | £52.98 | |

| 5 Metre Kit | 4 | 5 | 2 | 2 | 1 | 1 | B4-TB-04-5-A-BLK | £55.50 | |

| 7.5 Metre Kit | 4 | 7.5 | 2 | 2 | 1 | 1 | B4-TB-04-7-A-BLK | £57.42 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

Each kit consists of:

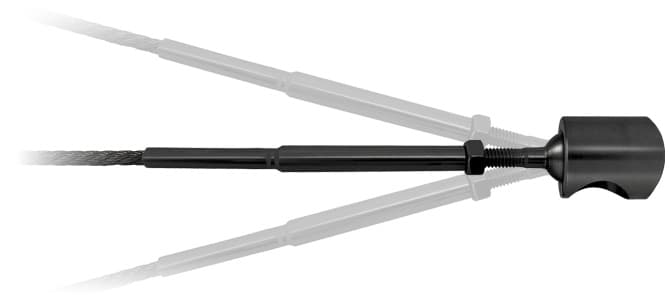

- 4mm diameter 7x7 blackened stainless steel rope

- Two scalloped mounting sockets to fit neatly onto 42.4mm posts

- One attached ball & one removable threaded ball

- One tension adjuster with lock nut

- Supplied complete with all relevant fixings

The Essential Partner

Want a full black Balustrade?We can now powder coat our premium stainless steel balustrade to a stylish black finish. This is a bespoke service, with all components being manufactured to order. For further information simply contact our sales and technical team on 01302 752 504 or email us at info@s3i.co.uk |

|

Installation Advice

It's important to note that before installing any type of balustrade or railing system, it's always a good idea to consult with your local building control to ensure that the installation meets all necessary safety and building codes.

Planning your project in advance and taking the necessary steps to ensure that you have the correct number of posts, wires, and fittings, you can help ensure a successful and hassle-free installation of your balustrade wire kit.

By spacing the balustrade wires at no more than 100mm apart, you can help ensure that the system is safe and secure, and that it meets all necessary building codes and regulations.

As a general guideline, the recommended spacing for vertical posts is 1.5 meters apart (upto a maximum of 2 metres), this ensures that the frame is strong and stable, and can support the weight and tension of the wires.

When cutting your wire for your balustrade wire system, it's important to be as accurate as possible and to double-check your measurements before making any cuts.

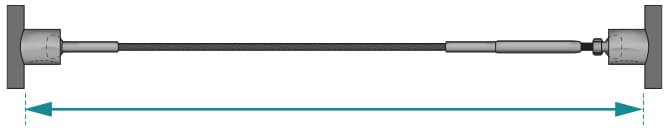

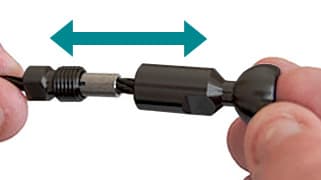

Each cable will have an adjustment of plus or minus 20mm.

Corners and Angles?

Can cables run up staircases or steps?

Yes, it is possible for cables to run up staircases or steps, our wire balustrade is designed to accommodate angles.

The smart design of our ball and socket joint allows for 42 degree articulation, which is the maximum allowable rake angle permitted in current building regulations.

Can run the cable railing round corners?

No. It is not recommended to run the cable railing around corner posts. This is because it can be difficult to apply equal tension to the cables when passing them through corner posts, which can result in an uneven and potentially unsafe installation.

Instead, it is recommended to terminate the wire rope balustrade at each side of a corner post, and to begin a new run of cable on the other side of the corner.

Cable lengths?

Balustrade cables can be run up to 7.5 metres in length, however, it's important to note that intermediate posts are required to ensure proper tension and stability.

One helpful tip for minimizing the number of cables required in a balustrade wire system is to pass the cables through any inline intermediate posts. This can help reduce the overall number of cables required.

DIY Installation Instructions

Need some help?Simply download and print our installation advice sheet for the Tube Mount Balustrade Wire Kit. |

|

1. Getting Started

It is a good idea to layout your design prior to drilling any holes. You can use a pen or chalk to mark the locations for your posts, and to mark the drilling locations for any holes that will be needed to install your posts or fittings

2. Drill Pilot Holes

Posts will require drilling and tapping with M6 thread holes for attachment of balustrade socket hubs.

To tap M6 holes, you will need a special drill bit that is designed for adding internal threads.

We offer a wide range of balustrade tools and accessories to make your installation as smooth as possible.

3. Align Socket

To align the socket, you will need to thread a M6 screw through the centre hole of the socket and position it on the post. It's important to ensure that the socket is aligned properly and that the opening is pointing downwards for a neat and tidy finish.

4. Fix Socket

Use a hex head key, simply tighten the M6 screw until your socket is securely fixed to the post.

5. Prepare Pre-Fixed Ball End

To prepare the pre-fixed ball end, you should unscrew the ball end to reveal approximately 20mm of thread. This thread will be used later to apply your final wire tension once the cable is installed.

6. Mounting Pre-Fixed Ball End

To mount the pre-fixed ball end, you simply insert it into the open mouth of the underside of the mounting hub and pull it into position, so it is securely seated in the mounting hub.

7. Mark Your Wire For Cutting

The next step is to mark the wire rope for cutting. To do this, you need to pull the cable over to the opposite post and align it to the spanner flat of the DIY compression fitting.

Mark your wire ready for cutting with a pen or chalk.

Note: The stand off from the mounting hub is 30mm.

8. Cut Wire

Cut your wire to required length, you should always use a good quality Wire Rope Cutter to give a clean and accurate cut.

Remember - measure twice and cut once.

Cutting the wire too short can be a costly mistake.

The adjustment range for each cable is typically plus or minus 20mm, which is sufficient to allow for cable tensioning.

9. DIY Compression Fitting

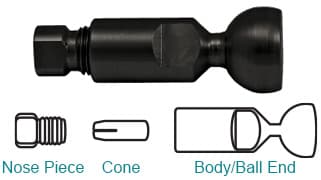

Prepare the DIY ball end fitting for installation.

Unscrew your DIY compression fitting to reveal its three separate parts: the Nose Piece, the Compression Cone, and the Ball End.

Tip: keeping the components in the order that they will be reassembled will make the assembly process much easier and quicker.

10. Thread Nose Piece onto Wire

Simply insert the nose piece onto the open wire rope end (ensuring the thread end is towards the end of your wire).

11. Thread Cone onto Wire

Insert the compression cone onto the wire and push fit into the nose piece chamber.

12. Place Ball End onto Wire

Take the ball end body and push onto the wire, align and bring the three component parts together by simply screwing the ball end onto the nose piece.

13. Secure Ball End Fitting

To secure ball end fitting use a pair of 8mm and 9mm spanners to screw the two sections together until the wire rope is securely fixed in place.

14. Mount DIY Ball End Fitting

Mount the DIY ball end into the open mouth of the underside of the mounting hub and pull into position.

Note: if you require more slack in your wire to insert the DIY end you can unscrew the fixed end ball tensioner to expand to the required length.

15. Tension Wire

With the DIY end in position, return to the pre-fixed ball end and screw in the thread using a 5mm spanner to achieve the desired wire tension.

Once tension is achieved tighten the lock nut on the fixed ball tensioner in place using a 10mm spanner.

Important: ensure that the wire rope is not allowed to twist during tensioning, as this could cause damage to the wire or fitting.

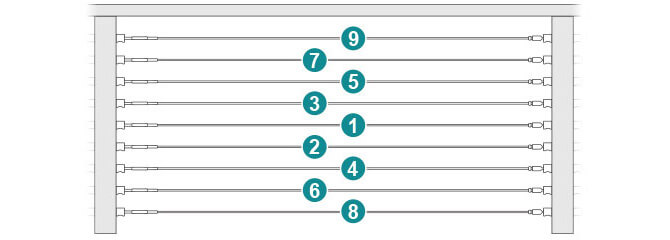

To tension balustrade wires, always start from the centre and work outwards, this will help ensure that the tension is distributed evenly.

Getting Started: Once all the wires are installed and loosely tensioned, you can begin to tighten each wire in turn by slight increments. Start with the center wire and gradually increase the tension until it is fully tightened and secure. Then move on to the next wire, working outwards from the center, and repeat the process. Continue to tighten each wire in turn until all the wires are fully tensioned and the balustrade system is solid and secure.