Eye Bolt - Marine Grade Stainless Steel

Eye Bolt with Metric Thread in A4-AISI 316 Grade Stainless Steel

General purpose stainless steel eye bolts suitable for a wide range of uses such as DIY projects, displays and gardens where a secure attachment point is needed.

Eye Bolt - Stainless Steel

| Options | Pack Size | D | L (mm) |

H (mm) |

C (mm) |

B (mm) |

A (mm) |

Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|---|---|---|

| M6 Eye Bolt | 1 | M6 | 10 | 42 | 6 | 16 | 16.8 | EB-M6 | £1.19 | |

| M8 Eye Bolt | 1 | M8 | 13 | 49 | 8 | 20 | 18.6 | EB-M8 | £1.61 | |

| M10 Eye Bolt | 1 | M10 | 18 | 63 | 10 | 25 | 24 | EB-M10 | £2.98 | |

| M12 Eye Bolt | 1 | M12 | 20 | 74 | 12 | 30 | 29 | EB-M12 | £4.74 | |

| M16 Eye Bolt | 1 | M16 | 28 | 91 | 14 | 35 | 33 | EB-M16 | £10.72 | |

| M20 Eye Bolt | 1 | M20 | 30 | 102 | 16 | 40 | 39 | EB-M20 | £16.88 | |

| M24 Eye Bolt | 1 | M24 | 38 | 128 | 20 | 50 | 49 | EB-M24 | £29.10 | |

| M30 Eye Bolt | 1 | M30 | 45 | 153 | 30 | 60 | 63 | EB-M30 | £45.85 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

Trade Packs - Bulk quantity packs offering you incredible value for money.

Eye Bolt - Stainless Steel

| Options | Pack Size | D | L (mm) |

H (mm) |

C (mm) |

B (mm) |

A (mm) |

Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|---|---|---|

| M6 Eye Bolt (50) | 50 | M6 | 10 | 42 | 6 | 16 | 16.8 | EB-M6-TP-50 | £53.46 | |

| M8 Eye Bolt (50) | 50 | M8 | 13 | 49 | 8 | 20 | 18.6 | EB-M8-TP-50 | £72.36 | |

| M10 Eye Bolt (50) | 50 | M10 | 18 | 63 | 10 | 25 | 24 | EB-M10-TP-50 | £133.92 |

Eye Bolt - Stainless Steel

| Options | Pack Size | D | L (mm) |

H (mm) |

C (mm) |

B (mm) |

A (mm) |

Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|---|---|---|

| M12 Eye Bolt (25) | 25 | M12 | 20 | 74 | 12 | 30 | 29 | EB-M12-TP-25 | £106.64 |

Key Features:

|

316 grade stainless steel. |

|

Metric Thread. |

Information

Strong eye bolt with metric thread to create a secure fixing point.

Manufactured from 316 grade stainless steel, suitable for use in harsh marine environments.

Metric thread sizes: M6, M8, M10, M12, M16, M20, M24, M30.

These eye bolts are not load rated and therefore not suitable for lifting environments.

When using eye bolts, it's essential to ensure that they are properly installed.

Eye bolts should be inspected regularly for wear and damage, and they should be installed in a manner that ensures stability and safety.

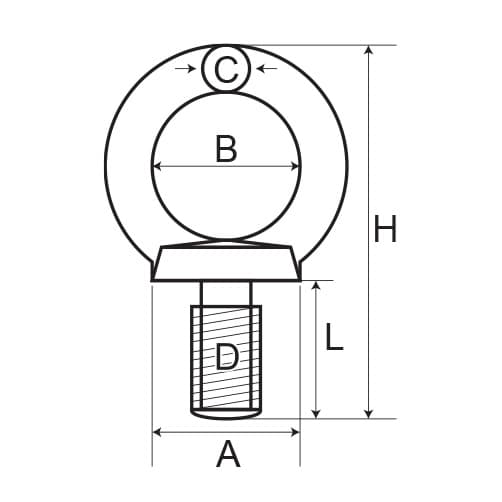

Dimension Information:

PDF Data Sheet

Download Eye Bolt Dimension Information

Need Load Rated Eye Bolts?

Lifting Eye Bolts - CE marked with working load limit - DIN 580 specification.

Metric thread - Forged A4-AISI 316 stainless steel

Questions & Answers

Reviews

You may also be interested in

Lifting Eye Bolts - CE Marked - DIN 580.

Lifting Eye Nuts - CE Marked - DIN 582.

Injection Resin for anchor points.