Sta-Lok Wedge 7 Strand for Sta-Lok Swageless Fittings

Sta-Lok Wedge for 7 Strand Wire Rope - 316 Stainless Steel

Sta-Lok wedges must be replaced where Sta-Lok terminals are being re-used with 7 strand stainless steel wire rope.

Sta-Lok Wedge 7 Strand - Swageless Fitting

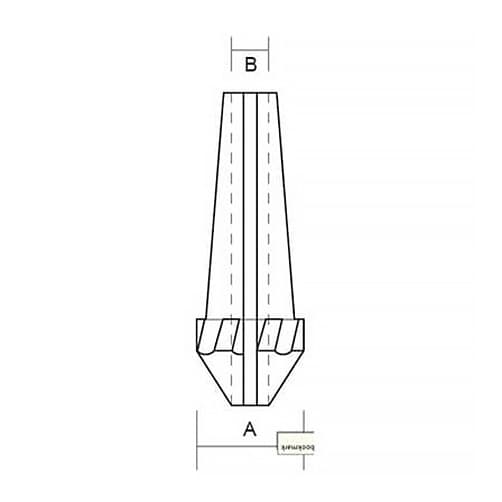

| Options | Wire (mm) |

A (mm) |

B (mm) |

Pack Qty | Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|

| 3mm Wedge | 3 | 4.74 | 1.3 | 5 | 127-03 | £41.30 | |

| 4mm Wedge | 4 | 6.43 | 1.6 | 5 | 127-04 | £49.19 | |

| 5mm Wedge | 5 | 7.62 | 2 | 5 | 127-05 | £60.68 | |

| 6mm Wedge | 6 | 9.78 | 2.3 | 5 | 127-06 | £69.59 | |

| 7mm Wedge | 7 | 11.43 | 2.6 | 5 | 127-07 | £92.22 | |

| 8mm Wedge | 8 | 12.7 | 3.2 | 2 | 127-08 | £46.07 | |

| 10mm Wedge | 10 | 15.95 | 3.7 | 2 | 127-10 | £64.80 | |

| 12mm Wedge | 12 | 19.05 | 4.8 | 1 | 127-12 | £36.43 | |

| 14mm Wedge | 14 | 23.16 | 5.5 | 1 | 127-14 | £45.42 | |

| 16mm Wedge | 16 | 26.97 | 6.8 | 1 | 127-16 | £61.74 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

The 7 strand replacement cone can be fitted on site using very simple hand tools.

Can be used for 7x7 and 7x19 stainless steel wire rope construction.

Must NOT be used for Dyform or compacted strand wire ropes.

Manufactured from 316 grade stainless steel.

Laser marked for easy identification.

Dimension Information:

PDF Data Sheet

Download Sta-Lok 7 Strand Wedge Dimension Information

Sta-Lok Wire Connector Terminals - Technical Information - How to assemble

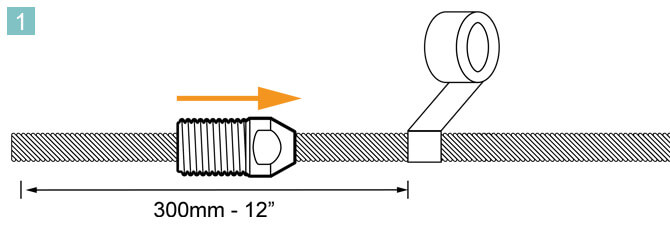

1. Cut wire rope and slide socket component over wire.

Wind tape around wire approx 12" (300mm) from end. This will prevent the socket from sliding down the wire.

TIP: If using a hacksaw to cut your wire rope, wind tape around wire to ensure a neat cut.

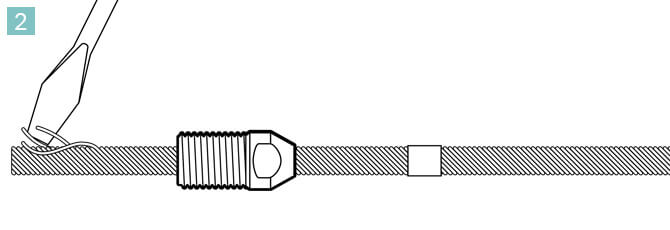

2. Unravel outer strands 2" to 3" (50-76mm) to expose central core.

TIP: Use a screwdriver to prise initial strands out of position.

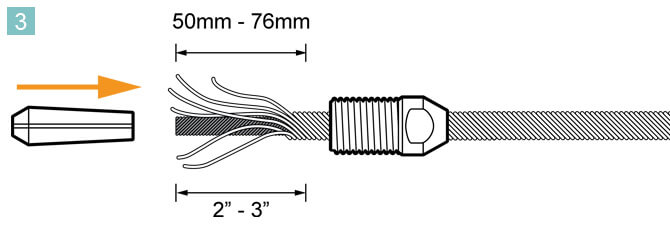

3. Slide wedge component over central core of wire rope.

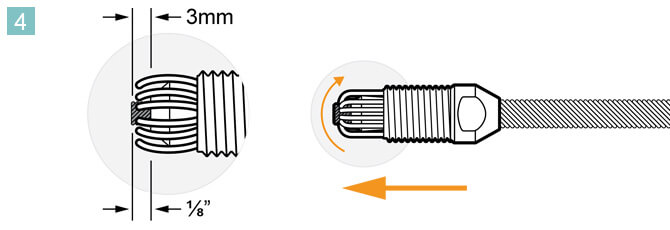

4. Reposition outer strands.

Turn outer strands either clockwise or anti-clockwise, depending on the lay of the wire, around the wedge. Ensure approx 1/8" (2-3mm) of the central core protrudes from the end of the wedge.

Outer strands should be evenly situated around the wedge. Care should be taken to ensure that a strand does not slip into the slit of the wedge.

TIP: Push the socket towards end of wire, while repositioning the outer strands, this will help control. When wire strands are in position, push socket firmly, as indicated to hold wires in position.

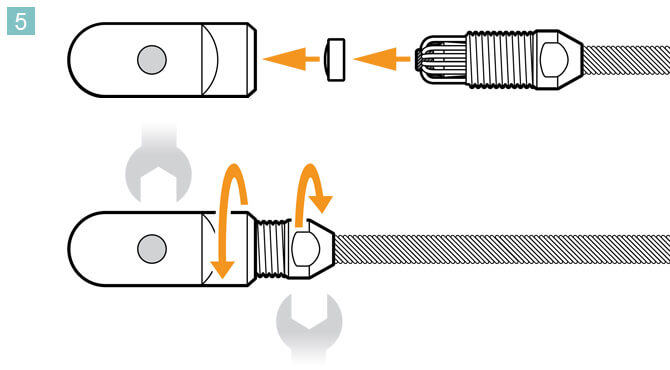

5. Final assembly.

Ensure former component sits in bottom of end fitting. Screw socket assembly into end fitting and tighten with spanners. The assembly is now complete.

TIP: Undue force is not required to terminate the wire.

Fitting instructions are supplied with each Terminal.

Questions & Answers

Reviews