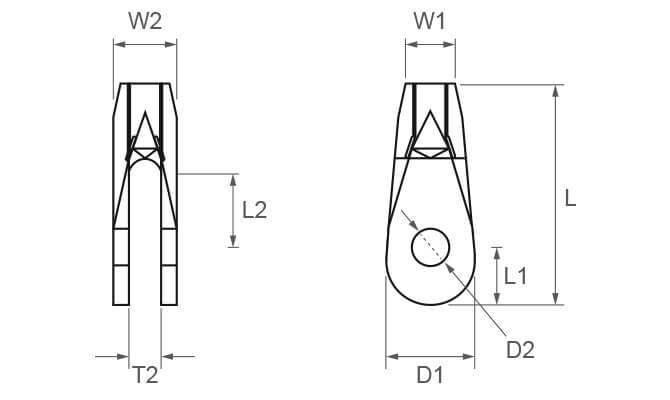

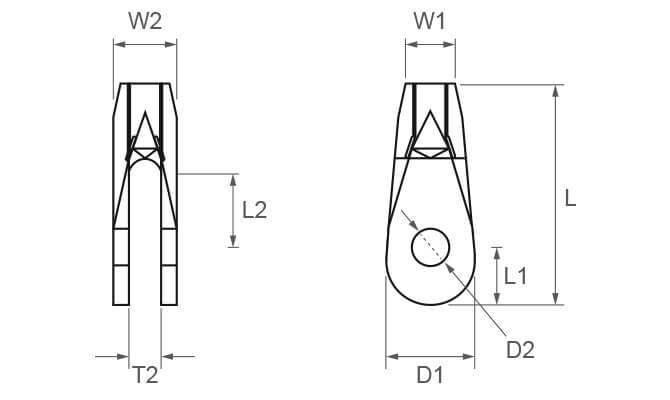

Cast Fork Dimensions

Fork Dimensions (in mm)

|

Please NoteCarbon assemblies are supplied with the following as standard: Galvanised fork assemblies with Self-colour carbon rods. |

Fork ends

Threaded fork ends are used to terminate bars and transfer load to the structure. Fork ends are cast components from M12 - M100 (dependent on material). The forks are threaded left hand or right hand depending on the tie rod arrangement and are generally tapped with a blind hole for corrosion detailing.

Dimensional information for our range of tie bar fork ends.

Fork Dimensions (in mm)

M12, M16, M20, M24 and M30

| Thread | M12 | M16 | M20 | M24 | M30 |

|---|---|---|---|---|---|

| Fork Length (L) | 90 | 112 | 132 | 155 | 189 |

| Diameter (W1) | 18 | 22 | 29 | 35 | 43 |

| Thickness (W2) | 24 | 28 | 35 | 42 | 52 |

| Jaw Gap (fork) +0/-2mm (T2) | 14 | 16 | 19 | 24 | 30 |

| Width (D1) | 32 | 43 | 51 | 62 | 79 |

| Pin Hole Diameter (D2) | 13 | 17 | 21 | 25 | 31 |

| Projection (L1) | 21 | 27 | 33 | 41 | 52 |

| Jaw Depth - Fork (L2) | 25 | 30 | 42 | 50 | 59 |

| Yield load - 'Design Load' (kN) | 30 | 82 | 127 | 184 | 292 |

Tie Bar Cast Fork

M36, M42, M48, M56 and M64

| Thread | M36 | M42 | M48 | M56 | M64 |

|---|---|---|---|---|---|

| Fork Length (L) | 217 | 238 | 266 | 313 | 348 |

| Diameter (W1) | 52 | 60 | 68 | 80 | 91 |

| Thickness (W2) | 62 | 74 | 84 | 95 | 120 |

| Jaw Gap (fork) +0/-2mm (T2) | 34 | 39 | 44 | 49 | 59 |

| Width (D1) | 93 | 107 | 121 | 145 | 167 |

| Pin Hole Diameter (D2) | 37 | 43 | 49 | 57 | 65 |

| Projection (L1) | 61 | 69 | 78 | 96 | 110 |

| Jaw Depth - Fork (L2) | 70 | 78 | 87 | 106 | 120 |

| Yield load - 'Design Load' (kN) | 425 | 583 | 766 | 1056 | 1392 |

Tie Bar Cast Fork

M76, M90 and M100

| Thread | M76 | M90 | M100 |

|---|---|---|---|

| Fork Length (L) | 420 | 498 | 575 |

| Diameter (W1) | 108 | 129 | 143 |

| Thickness (W2) | 148 | 170 | 181 |

| Jaw Gap (fork) +0/-2mm (T2) | 76 | 86 | 91 |

| Width (D1) | 199 | 246 | 287 |

| Pin Hole Diameter (D2) | 78 | 96 | 111 |

| Projection (L1) | 131 | 161 | 188 |

| Jaw Depth - Fork (L2) | 141 | 171 | 197 |

| Yield load - 'Design Load' (kN) | 1999 | 2879 | 3605 |