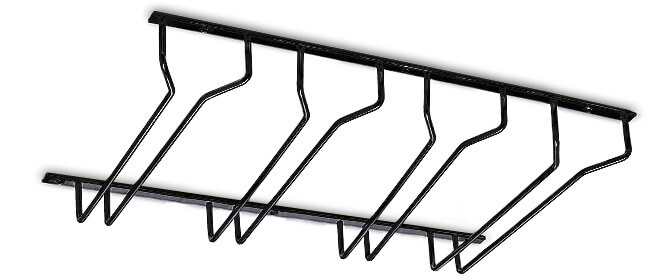

Glass Rack for Wide Glassware - Anthracite

Wide Coupe Glassware, 4 Column Hanger Storage Solution in Anthracite Design

Glass rack in a very dark grey (near black) finish with four sections for wide stemmed glassware, designed for underside mounting and is ideal for commercial bars and restaurants.

Glass Rack - 4 Column - Mod 877

| Options | Finish | Depth (L) (mm) |

Width (mm) |

Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|

| Glass Rack, 300mm | Anthracite | 300 | 500 | 11.0877.300.26 | £118.32 | |

| Glass Rack, 350mm | Anthracite | 350 | 500 | 11.0877.350.26 | £130.42 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

Important: Depth (L) measurement is hole centre to hole centre, allow additional 30mm for installation.

Key Features:

|

Anthracite finish. |

|

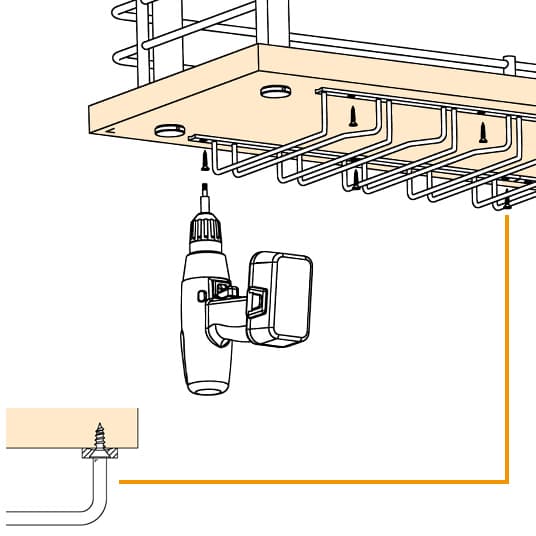

Drill required for installation. |

|

Countersunk screws are supplied for wood mount installation. |

Anthracite Black Glass Rack - 4 Column

Anthracite design suspended glassware storage solution suitable for coupe glassware.

Glass rack manufactured from Zamak with a PVD coating to give a hard-wearing anthracite finish.

Strong and safe storage solution that offers fantastic glass organisation with quick and easy access.

Space of 125mm between the stem rails, suitable for wide stemmed glass, such as wine glasses, cocktail glasses.

All racks are 500mm wide with a choice of 300mm and 350mm, depths available, (+ 30mm depth for installation).

Easy DIY installation using countersunk screws, mounting onto the underside of shelves, cupboards and cabinets.

Designed for indoor use.

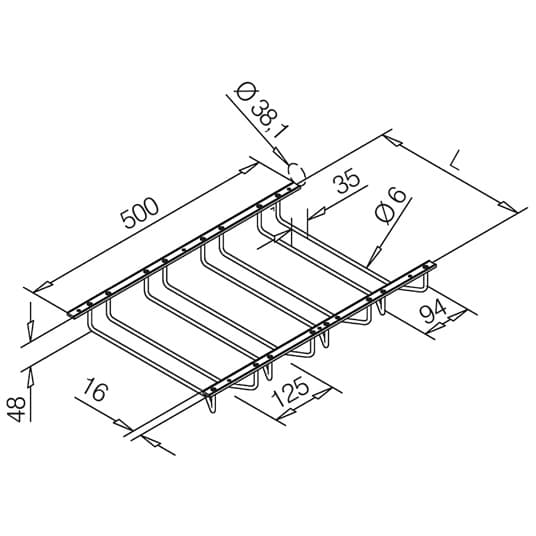

Dimensions

Width: 500mm

Depth: 300mm, 350mm

Height: 48mm

Glass stem reception: 35mm

Glass base reception: 85mm

Rail Ø: 6mm

Downloads:

PDF Data Sheet

Download 4 Column Glass Rack in Anthracite - Information

|

Zamak Construction - PVD CoatingZamak is a family of alloys with a base metal of zinc with elements of aluminium, magnesium and copper. PVD (Physical Vapour Deposition) coatings are usually harder and more corrosion resistant than coatings applied by electroplating and tend to have high temperature and good impact strength, excellent abrasion resistance and durability. |