Lifting Bow Shackle - Stainless Steel - Standard Pin

Tested and Certified Lifting Bow Shackle - Screw Pin - 17/4PH High Tensile Stainless Steel

Tested and certified stainless steel bow shackle for general lifting applications - Supplied with standard pin: Type A - forged collar pin with eye, standard length.

|

Special OrderEvery shackle is proof load tested and certified at our UK manufacturing facility. We can confirm the lead time upon enquiry/order. |

Lifting Bow Shackle Standard Pin

| Options | P (mm) |

B (mm) |

J (mm) |

W (mm) |

L (mm) |

WLL (Tonnes) |

Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|---|---|

| PHB-08-A Bow Shackle | 10 | 8 | 16 | 24 | 32 | 0.8 | PHB-08-A | £39.78 | |

| PHB-15-A Bow Shackle | 12.7 | 10 | 20 | 30 | 40 | 1.5 | PHB-15-A | £45.18 | |

| PHB-25-A Bow Shackle | 16 | 12.7 | 25 | 38 | 50 | 2.5 | PHB-25-A | £56.34 | |

| PHB-40-A Bow Shackle | 19 | 16 | 32 | 48 | 64 | 4 | PHB-40-A | £90.95 | |

| PHB-55-A Bow Shackle | 22.2 | 19 | 38 | 57 | 76 | 5.5 | PHB-55-A | £153.66 | |

| PHB-75-A Bow Shackle | 25.4 | 22.2 | 44 | 66 | 88 | 7.5 | PHB-75-A | £239.39 | |

| PHB-90-A Bow Shackle | 28.6 | 25.4 | 51 | 76 | 102 | 9 | PHB-90-A | £349.32 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

Information

|

Made In BritainThis stainless steel lifting bow shackle with standard screw pin is manufactured here in the UK. |

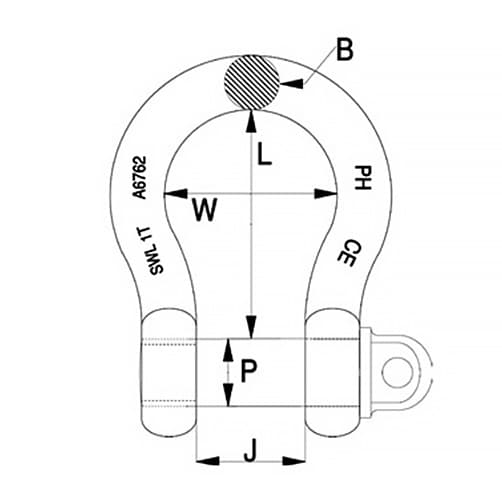

Dimension Information:

PDF Data Sheet

Download Lifting Bow Shackle - Standard Pin - Dimension Information

Technical

PH Lifting Shackles - High Tensile Stainless Steel

PH LIFTING SHACKLE TECHNICAL SHEET download here

PH High Tensile Lifting Shackles - 17/4 stainless steel, UK Made, Certified and CE marked WLL.

PH lifting shackles are manufactured from 17/4 stainless steel and are proof-tested to twice their working load limit (WLL) using equipment calibrated to BS EN 10002-2 and NAMAS NIS 0424.

Our 17/4 PH stainless lifting shackles are available in 3 pin types.

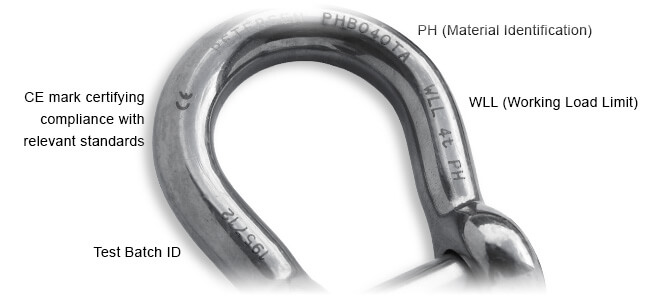

PH Shackle Product Marking

Each and every lifting shackle which details the CE mark is individually tested and identified.

The identification number not only provides a trace to the WLL test but also to the batches of material used.

This means that from any shackle we can trace right back to material source and provide material/mill certificates relative to the materials used for that part.

Proper Use

Inspection of Lifting Shackles before use

Before any piece of equipment is first put into use it should be examined for signs of damage.

If it is known, or suspected, that the equipment has been subjected to an excess load or it shows any sign of cracking, splitting or deformation it must be destroyed.

It is required that the equipment is regularly inspected and that the inspection should take place in accordance with the safety standards given in the country of use. This is required because the products in use may be affected by wear, misuse, overloading etc. with a consequence of deformation and alteration of the material structure.

Inspection should take place at least every 6 months and even more frequently when the equipment is used in severe operating conditions.

Other Lifting Products

Lifting Turnbuckles - Tested and certified turnbuckles, engineered for lifting applications. |

Tufnol Lifting Blocks - Proof tested and supplied with test batch ID and full certification. |

Safety Shackles - Ideal for applications where corrosion resistance is of significant importance. |