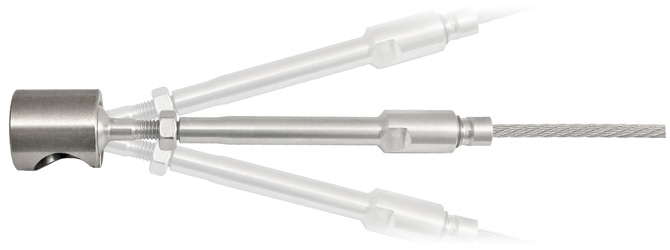

Ball End Socket - Flat Mount - 316 Stainless Steel

Wire Balustrade Flat Mounting Socket for Cable Ball End Tensioners and Fittings.

Ball end socket creates a secure fixing point on flat surfaces to terminate wire balustrade ball end fittings, suitable for indoor and outdoor applications.

Ball End Socket - Flat Mount - Balustrade Wire

| Options | Grade | A (mm) |

B (mm) |

ØD (mm) |

ØH (mm) |

Quantity | Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|---|---|

| Flat Ball Socket | 316 | 22 | 6.3 | 22 | 6.3 | 1 | BCFM6-C | £7.87 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

Don't forget to add your screw fixing...

We do NOT supply screw fixings with this socket, you can simply add a fixing to suit your preferred mounting surface.

Timber and Masonry Mount70mm Stainless Steel Wood Screw recommended for direct mounting on to hardwood timber (can also be used in conjunction with a plastic wall plug for masonry walls). |

Key Features

|

316 grade stainless steel. |

|

Screwdriver required for installation. |

|

Drill required for installation. |

Flat mounting ball end socket manufactured from 316 marine grade stainless steel, strong, tough and long lasting in the most harsh of conditions.

Provides a secure fixing point for our wire rope swageless ball end fittings and tensioners.

Ingenious design allows up to 42 degrees of cable articulation for angles and inclines.

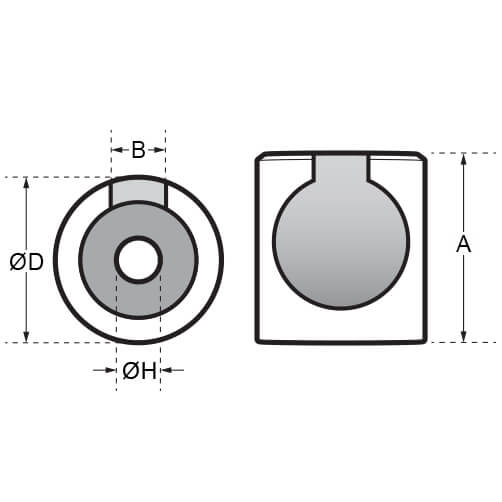

Dimension Information:

- Height (A): 22mm

- Diameter (ØD): 22mm

- Hole (ØH): 6.3mm

- Opening (B): 6.3mm

You may be interested in...

Swageless Ball End Fitting for stainless steel wire rope.

Swageless Ball End Tensioner for wire rope.

Hand Held Cutters for stainless steel wire rope.

Installation Advice

We always recommend you plan your project in advance to ensure you have the correct number of posts, wires and fittings, remembering to take into consideration end post and corner post termination clearance and position.

Stainless steel wire cables should be spaced a maximum of 100mm apart, with vertical posts spaced at a maximum of 2 metres apart to ensure a strong frame.

Simply view or download our installation advice below to suit your chosen fixing method.

Installation Example: Mounting On To Hardwood Posts

For a quick and easy installation on to hardwood posts you will require a few household tools: tape measure, pen or chalk, cross head screwdriver and a drill.

Getting StartedLayout your design onto the relevant surface with a pen or chalk prior to drilling any holes. |

|

Drill Pilot HolesThe stainless steel wood screw allows direct installation into hardwood timber (such as oak) or, if combined with the correct plastic plug, it is attachable to almost any masonry surface (we recommend a 3mm drill piece for direct installation or a 7mm if inserting a plastic plug). |

|

Mount Socket into PositionUsing a screwdriver, fix the ball end socket using the stainless steel wood screws. |

|

Alternative Fixing Option

You can use a M6 x 16mm countersunk hex head screw, which will allow for flush mounting onto stainless steel box section posts and uprights.

Stainless Steel Post MountM6 x 16mm Countersunk Hex Head Screw is recommended for mounting onto flat profile stainless steel posts. (Please Note: Posts will require drilling and tapping) |

Questions & Answers

Reviews