Lifting Turnbuckle - Eye to Jaw - Stainless Steel

Turnbuckle with Eye and Jaw, Load Tested & CE Marked for Lifting Applications

Eye to jaw rigging screws specifically manufactured for lifting. Made in the UK from stainless steel EN10088 1.4404 (Marine Grade 316L).

|

Special OrderEvery turnbuckle is proof load tested to 2 x WLL and certified at our UK manufacturing facility. We can confirm the lead time upon enquiry/order. |

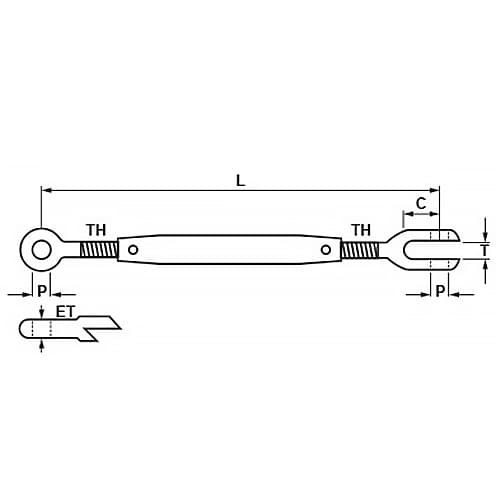

Lifting Turnbuckle Eye - Jaw

| Options | TH (UNF) |

WLL (Kg) |

Wire (mm) |

P (Jaw) (mm) |

P (Eye) (mm) |

ET (mm) |

T (mm) |

Min L (mm) |

Max L (mm) |

Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3mm Eye-Jaw | 1/4" | 200 | 3 | 6 | 6.35 | 5 | 6.2 | 127 | 197 | LBFE-03 | £63.36 | |

| 4mm Eye-Jaw | 5/16" | 325 | 4 | 8 | 8 | 6.5 | 7.9 | 154 | 232 | LBFE-04 | £72.10 | |

| 5mm Eye-Jaw | 3/8" | 500 | 5 | 9.5 | 9.53 | 7.8 | 9.9 | 189 | 289 | LBFE-05 | £88.22 | |

| 6mm Eye-Jaw | 7/16" | 700 | 6 | 11 | 11.1 | 9.5 | 10.9 | 207 | 316 | LBFE-06 | £108.98 | |

| 7mm Eye-Jaw | 1/2" | 825 | 7 | 12 | 12.7 | 11.5 | 12.7 | 244 | 376 | LBFE-07 | £137.38 | |

| 8mm Eye-Jaw | 5/8" | 1325 | 8 | 14 | 14.3 | 13.5 | 13.5 | 300 | 456 | LBFE-08 | £211.02 | |

| 10mm Eye-Jaw | 5/8" | 1325 | 10 | 16 | 16 | 15 | 15.8 | 325 | 480 | LBFE-10 | £235.12 | |

| 12mm Eye-Jaw | 3/4" | 1825 | 12 | 19 | 19.05 | 17.5 | 17.8 | 373 | 544 | LBFE-12 | £466.90 | |

| 14mm Eye-Jaw | 7/8" | 2500 | 14 | 22 | 22.2 | 21.5 | 22 | 415 | 610 | LBFE-14 | £639.22 | |

| 16mm Eye-Jaw | 1" | 3300 | 16 | 25 | 25.4 | 23.5 | 25 | 485 | 724 | LBFE-16 | £955.56 | |

| 19mm Eye-Jaw | 1 1/8" | 4300 | 19 | 28 | 28.58 | 27.5 | 28.2 | 548 | 818 | LBFE-19 | £1,578.68 | |

| 22mm Eye-Jaw | 1 1/4" | 5500 | 22 | 32 | 32 | 31 | 31.8 | 595 | 879 | LBFE-22 | £2,132.57 | |

| 26mm Eye-Jaw | 1 3/8" | 6600 | 26 | 35 | 35 | 33.5 | 34.8 | 672 | 996 | LBFE-26 | £2,842.44 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

Turnbuckle with threaded eye and jaw end fittings designed and engineered to perform with the highest levels of confidence.

Every turnbuckle is proof load tested to 2 x WLL and certified at our UK manufacturing facility.

The factor of safety applied in regard to WLL (Working Load Limit) is 6:1.

All products in this range of lifting turnbuckles are CE marked and manufactured in accordance with the Machine Directive 2006/42/EC.

Each product is also marked with unique manufacturing numbers allowing full traceability.

Inspection certificate BS EN 10204 3.1b available on request.

This range of lifting turnbuckles are presented in a high quality finish and excellent polish and are ideal for lifting applications where a high level of corrosion resistance is needed.

Dimension Information:

PDF Data Sheet

Download Lifting Turnbuckle Dimension Information

Typical Applications

- Water Utility Applications

- Corrosive Environments

- Chemical Installations

- Off-Shore Lifting

- Marine Environments

- Tethering

- General Lifting

Other lifting products

Lifting Shackles - high Tensile stainless steel 17/4 PH. Certified & CE marked, designed and manufactured for general lifting applications. |

High quality general purpose Lifting Blocks. All lifting blocks are proof tested and supplied with test batch ID and full certification. |

Safety Pin Lifting Shackles should be used in applications where corrosion resistance is of significant importance. |