Back Mount Balustrade Cable Wire System, Self Assembly

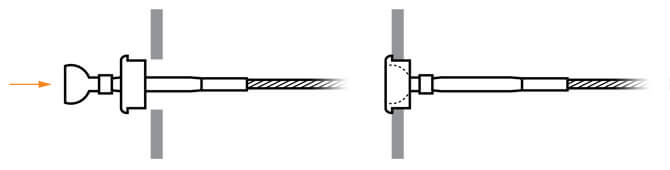

Back mounting sockets and compression (swageless) terminations for balustrade cable

Complete back mounting balustrade wire and fixings kit. Ingenious ball and socket design ideally suited to straight runs, with all components produced from 316 marine grade stainless steel.

Back Mount Cable Rail, Self Assembly

| Options | Wire Ø (mm) |

Wire Length (metre) |

Back Mount Sockets | Tension Fitting | DIY End Fitting | Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|---|

| 1m Back Mount Wire : | 4 | 1 | 2 | 1 | 1 | B2-F-04-1-A | £31.50 | |

| 2m Back Mount Wire | 4 | 2 | 2 | 1 | 1 | B2-F-04-2-A | £32.76 | |

| 3m Back Mount Wire : | 4 | 3 | 2 | 1 | 1 | B2-F-04-3-A | £33.96 | |

| 5m Back Mount Wire : | 4 | 5 | 2 | 1 | 1 | B2-F-04-5-A | £37.80 | |

| 7m Back Mount Wire : | 4 | 7 | 2 | 1 | 1 | B2-F-04-7-A | £40.32 | |

| 10m Back Mount Wire : | 4 | 10 | 2 | 1 | 1 | B2-F-04-10-A | £43.46 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

Designed and produced in the UK.

Please allow 3 to 5 working days from order for manufacture and delivery.

Each Back Mount Balustrade Wire Kit consists of

- 4mm 7x7 Stainless steel wire rope

- Two back mounting sockets

- One compression (swageless) ball for self-assembly

- One threaded ball attached

- One swage adjuster with lock nut

The wire is supplied with the adjuster end with threaded ball fixed onto the wire.

The ball terminal is supplied for assembly by the user. Tension is achieved by rotating the threaded ball in the swageless adjuster, tightening to suit, then locking with the lock nut.

Installation

Back mount socket dimensions:

D = 19mm

S = 7mm

L = 3mm

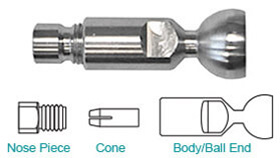

Stainless Steel Compression Ball Fitting Instructions

1. Cut WireCut your wire to required length, we recommend using a set of good wire rope cutters to give you a neat and tidy cut. Remember - measure twice, cut once! Please be as accurate as possible. |

|

2. DIY Compression FittingYou are now ready to attach the DIY end fitting. The first step is to take apart your DIY compression fitting. |

|

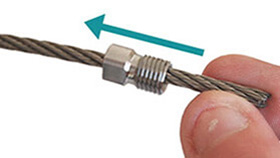

3. Thread Nose Piece onto WireTaking the blank cable end place the nose piece over the stainless steel wire rope (ensuring the thread end is towards the end of your wire). |

|

4. Thread Cone onto WireThread the cone onto the wire and push into the threaded cone chamber. |

|

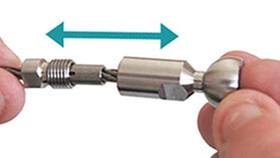

5. Place Ball End onto WireTake the stainless steel body and push onto the wire, eventually bringing the three component parts together. Turn in opposite directions to thread them together. |

|

6. Secure Ball End FittingUsing a pair of 8mm and 9mm spanners screw the two sections together until tight. |

|

You may be interested in...

Back Mount Balustrade Wire, Made to measure.

Vertical Wire Balustrade, Wood mount.

Vertical Wire Balustrade, Stainless steel tube mount.

Wire Balustrade Systems, for indoor and outdoor.